|

Slag piled high

in East

Helena

If you've traveled through East Helena,

you probably noticed the huge pile of black

material at the ASARCO Smelter along the

highway. The material, called

"slag", is waste product produced as ASARCO

removed lead from the ore.

Getting the lead out . . .

For more

than a century, crushed ores

containing galena (PbS) were brought to East

Helena from as far away as Chile and Korea.

Once at the smelter, the ores were "roasted"

in order to remove the sulfur. The sulfur combined with oxygen to form a gas called sulfur dioxide, a pollutant that contributes to acid rain. A law called the Clean Air Act, which went into effect in the early 1970s, required that industries like the smelter remove this emission. A pollution-control device called a "scrubber" had to be installed to do this. The roasting

formed a material called "sinter," which was a

mixture of lead oxide (PbO) and other rock

materials. Next

the sinter had to be melted. Crushed

limestone and quartz were added to make it

easier to melt the mixture. Once the material

was melted, the heaviest stuff (lead) would

sink to the bottom of the tank. The molten

lead was then drained out through openings

in the bottom into molds where it

solidified.

Separation by melting . . .

This

separation by melting is called

smelting. The rest of the molten material,

which had been floating above the layer of

lead,

also solidified, forming the black waste

product called slag. For years the slag was

disposed of by dumping it along the

edge of the smelter property.

Other metals too . . .

Until its

closure in the spring of 2001, the

ASARCO Smelter shipped 10-ton pieces of

lead by rail to a refinery back east. The

refinery was able to separate trace amounts of

other valuable metals such as gold and silver.

In a typical year (early 1990s) the smelter's

bullion yielded the following:

69,000 tons of lead

3,500 tons of copper

690 tons of arsenic

150 tons of

bismuth

20,000,000 oz. of

silver

200,000 oz. of

gold Anaconda also

has piles of slag . . .

The smelter in

Anaconda was designed to extract copper

from the ores mined in Butte. The texture of

Anaconda's slag (CLICK HERE to see aerial photo.) is much different than the

slag in East Helena. East Helena's slag is

very "blocky," with pieces varying from

fist-size to much larger. In Anaconda the

slag is more like sand because the molten

slag was spilled into water, causing it to

harden and shatter into sand-sized pieces. In

fact Anaconda's slag has been used in sand

traps at the famous Old Works Golf

Course.

Trivia . . .

Country Music Hall of Fame singer, Charlie Pride, once worked at East Helena's smelter and starred on the Smelterite baseball team.

Below: A closer view of

the slag (looking toward Helena)

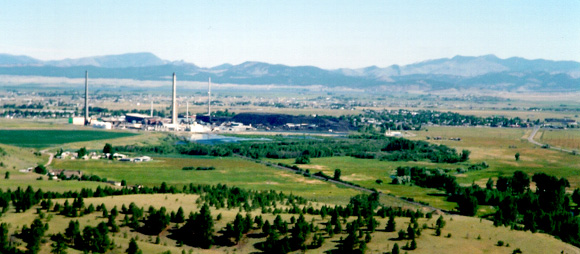

Below: A view from

the south (looking over the Helena

Valley)

Terms: ore, flux

|